Sausage Casing Manufacturers tell you whether it is safe to eat sausage casings or not, hope you can help

Much depends on what type of sausage is used and what type of casings are used. Natural casings are the submucosa of the intestines of pigs, sheep, cattle and sometimes horses. The intestines used to be rinsed, scraped and cleaned by hand, and more recently, machines have been used for mass production. The natural casings breathe, allowing the smoky and culinary flavors to penetrate the casings and permeate the meat, giving the sausage a rich, even flavor throughout the process. Natural Casings have a unique natural curve and sheen that connects the ends of the sausage in a rounded shape, making the sausage visually appealing.

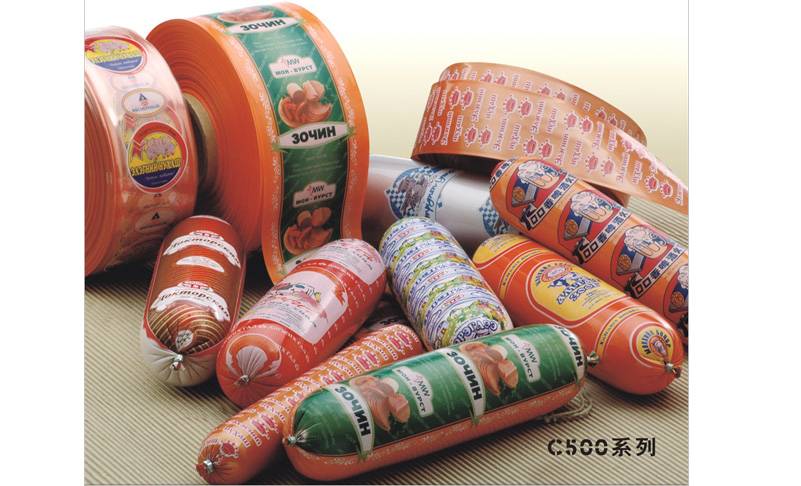

Artificial casings are made from collagen, cellulose, and even plastic and may be inedible. Artificial casings made from animal collagen are edible, depending on the source of the raw material. Collagen casings are mainly produced from collagen found in cow or pig skin, as well as bone and tendon. It can also be extracted from poultry and fish. They have been produced for more than 50 years and their share in the market has been increasing.

Sausage Casing

Typically, the cost of producing collagen sausages is significantly lower than the cost of making casings because of the higher production speed and lower labor requirements. The latest generation of collagen casings are typically more tender than natural casings, but do not exhibit the "snap" or "bite" of natural casings. The largest volume of collagen casings are edible, but a special form of thicker collagen casings are used for salami and large-bore sausages, where consumers typically peel the casings off the sausage. Collagen casings are less expensive to use, provide better weight and size control, and are easier to run compared to natural casings.

Cellulose, usually from cotton bark or wood pulp, is processed into viscose and then extruded into clear, tough casings for sausages and frankfurters. They are also angled for ease of use and can be treated with dyes to make braised meats. After cooking, the casings are peeled off to form skinless frankfurters. Cellulose mucilage solutions are combined with wood or, for example, abaca pulp to make large-diameter fibrous casings for bologna, cotto salami, smoked ham and other products sliced for sandwiches. This type is also permeable to smoke and water vapor. They can be flat or wrinkled, depending on the application, and can be pretreated with smoke, caramel color or other finishes.

Plastic shells are not edible. They can also be flat or wrinkled. Generally, smoke and water do not pass through the shells, so plastic is used for non-smoked products where high yields are expected. The inner surface can be laminated or co-extruded with a polymer that has an affinity for meat proteins, causing the meat to stick to the film and causing some loss when peeling off the shell, but higher yields overall due to better moisture control.

We hope the above sharing is helpful to you, the company also provides Clipping Machine, please feel free to contact us if you need